[thumbnail]

Project Overview

Wireless Electric Vehicle Charging in Micro Fulfilment Centres (WEVC-MFCs) is a project Flexible Power Systems (FPS) is leading in collaboration with Heriot-Watt University (HWU) and City of Edinburgh Council (CEC). The project is assessing three innovations designed to accelerate the transition of fleets to electric vehicles: shared charging hubs, dynamic charge scheduling across fleets and high-power wireless charging for Light Commercial Vehicles (LCVs).

The project is using 22kW wireless electric vehicle chargers (WEVCs) to accelerate turn-around times at the hubs and improve utilisation. Since this technology is not currently available for LCVs in the market yet, we have designed a real-world trial to demonstrate the feasibility and identify a pathway to an acceptable price point of this integration. This will be the first trial in the UK of high-powered wireless charging technology on light commercial vehicles (LCVs).

If the project is successful in proving its benefits, wireless charging technology could be applied to highly utilised vans in fleets across the UK to accelerate the transition to electric LCVs.

About James

James Derby, Chief Electrical Engineer at FPS, is leading the technical aspects of the project. He is a power electronics and machines specialist with more than 25 years of global experience in product development, manufacturing and applications engineering up to board level. As the Technical Lead, James and his team are responsible for the charger and vehicle selection, hardware integration, vehicle and charger data collection, as well as building the CCS rapid charging interface between vehicle and the WPT (Wireless Power Transfer) equipment.

Benefits of Wireless Charging

WEVC has the potential to mitigate fleet integration challenges by providing several benefits for both fleet operators and commercial vehicle users.

Firstly, WEVC expands the potential of opportunity charging by creating greater flexibility of charge point siting and faster initiation of charging sessions. Opportunity charging can extend vehicle effective range for a given battery pack size. This expands the number of situations EVs can be used in and also allows smaller battery packs to be used directly addressing range and payload constraints.

Secondly, WEVC can increase user acceptance through timesaving and safety benefits by removing cables and connectors from the process.

Finally, WEVC is future proofing for the advent of autonomous vehicles as it removes the requirement for manual intervention in the charging process.

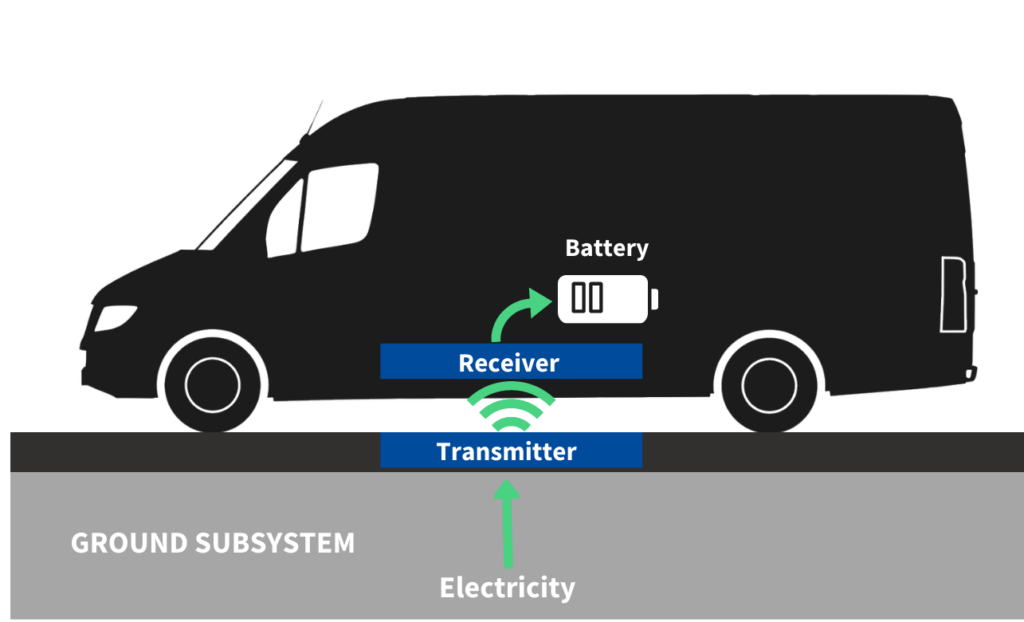

How Wireless Charging Works

Wireless electric vehicle charging is a technology originally developed for mass transit applications that enables vehicles to be charged through an inductive process via charging pads instead of a conductive process that relies on cables. To do this, electrical energy is converted and transferred at high frequency across an air gap from one magnetic coil in the charger to a second one fitted to the car. When the vehicle is parked over a charger on the ground beneath it, the 2 coils will be aligned to initiate highly efficient charging of the onboard vehicle batteries.

Integrating High Power Wireless Electric Vehicle Charging on LCVs

Whilst high power wireless charging has been used successfully in mass transit applications, its use in vans is new. To make this technology work in our fleet application requires us to overcome several challenges:

- Vehicle packaging – the charging systems are usually mounted on the underside of large transit buses. Our target vehicle, Vauxhall Vivaro-e, is considerably smaller.

- Vehicle/Charger Communications – buses where high power wireless charging has previously been deployed tend to rely on CHAdeMO a DC rapid charging protocol, whereas CCS is becoming the dominant standard for smaller vehicles like the LCVs used in our trial.

- Requirement for smart charging integration – the chargers also need to communicate with FPS’ proprietary fleet charger scheduling software for the trial.

Packaging

In the project we have chosen to address the packaging challenge through close collaboration with Vauxhall. Vauxhall are supporting the project by providing advanced access to the vehicles and CAD models so that an appropriate mounting strategy that does not reduce clearance excessively can be developed.

Communications

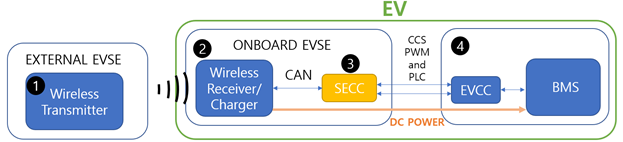

The vehicle/charger communications challenge requires the most effort. Whilst the WEVC equipment relies on a CHAdeMO standard, CCS is becoming the dominant charging standard for electric vehicles. The core of CCS is the standard ISO-15118. This defines the handshaking and client-server messages sent between the vehicle (client) and the server (charging station). As CCS is becoming the de-facto standard, we have made the decision to develop a CAN to ISO-15118 interface that will act as a translator between the WEVC vehicle assembly and the battery management system (BMS). As far as the vehicle assembly is concerned, the interface will be talking to the BMS via CAN messages, and the BMS will think it is talking to a charger via the PLC channel. An interface developed for the Vivaro-e will also allow us to integrate the WPT on any other CCS compliant vehicle, which will remove a barrier to deploying high powered wireless charging in this application.

The main components in the system above are:

- The Wireless charger/transmitter Ground Assembly (GA)

- The Wireless receiver Vehicle Assembly (VA)

- The Supply Equipment Charge Controller. This is the module that we are developing to work alongside the Wireless charging equipment.

- The Electric Vehicle Charge Controller (EVCC) and the Battery Management System (BMS).

Smart Charging Integration

The smart charging integration will rely on developing Open Charge Point Protocol interfaces with a variety of wireless and tethered charger back-office interfaces. This decision has been taken to ensure that the software can be rolled out to a broad range of charger makes and models without requiring extensive re-engineering.

What Happens Next?

The vehicles will be arriving around Christmas this year. Between now and then our team will be undertaking software development and design activity using loan vehicles from Vauxhall.

Integration activities will start in the New Year with the goal of releasing the vehicles to trial in March/April. Further updates will be provided here and through our newsletter as this exciting technical project progresses.

If you would like more information about our specialist hardware integration services contact us at info@flexpowerltd.com.